Printing Industry Standards Tolerances: Ensuring Quality and Precision

Greetings, Readers!

Welcome to our comprehensive guide on printing industry standards tolerances. In this article, we will delve into the world of printing, exploring the importance of adhering to standards and tolerances to achieve optimal quality and precision in the printing process. Whether you are a printing professional or simply curious about the industry, this article will provide valuable insights and knowledge.

Introduction

1. What are Printing Industry Standards Tolerances?

Printing industry standards tolerances refer to the acceptable variations and deviations permitted in the printing process. These standards help ensure consistency, accuracy, and quality in printed materials. They encompass a wide range of factors, including color accuracy, registration, image clarity, and much more.

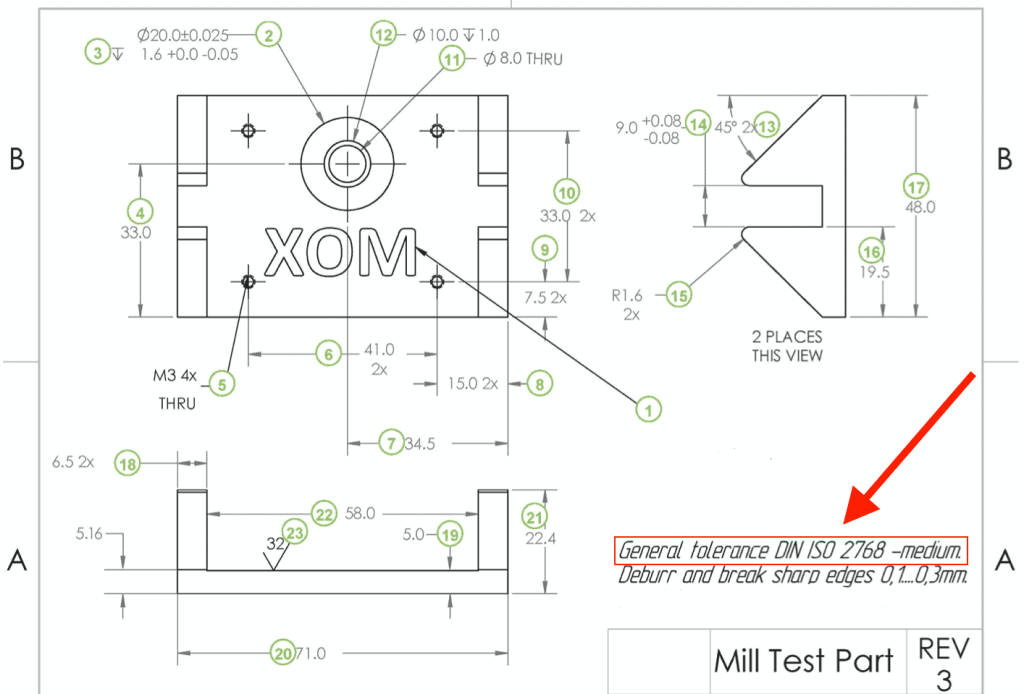

Image Source: xometry.eu

2. Who Establishes Printing Industry Standards Tolerances?

Printing industry standards tolerances are established by various organizations such as the International Organization for Standardization (ISO), the American National Standards Institute (ANSI), and the International Color Consortium (ICC). These organizations conduct extensive research, collaborate with industry experts, and develop guidelines to standardize printing processes.

3. When Should Printing Industry Standards Tolerances Be Applied?

Printing industry standards tolerances should be applied at every stage of the printing process, from prepress to post-press. It is essential to adhere to these standards from the design phase to the final production to ensure consistent and high-quality printed materials.

4. Where Are Printing Industry Standards Tolerances Used?

Printing industry standards tolerances are utilized in various printing applications, including commercial printing, packaging, labels, and signage. These standards are applicable to both digital and offset printing technologies and ensure uniformity across different printing platforms.

5. Why Are Printing Industry Standards Tolerances Important?

Printing industry standards tolerances play a crucial role in maintaining consistency and quality in printed materials. By adhering to these standards, printers can reduce waste, minimize errors, and achieve accurate color reproduction. Consistency in printing also enhances brand image and customer satisfaction.

6. How Are Printing Industry Standards Tolerances Implemented?

Implementing printing industry standards tolerances involves using calibrated equipment, employing skilled personnel, and following standardized procedures. Printers must regularly calibrate their machines, monitor color accuracy, and perform quality checks to ensure compliance with the established tolerances.

The Advantages and Disadvantages of Printing Industry Standards Tolerances

1. Advantages of Printing Industry Standards Tolerances

🔹 Ensures consistent color reproduction across print runs.

🔹 Reduces waste and improves resource efficiency.

🔹 Enhances brand identity and customer satisfaction.

🔹 Facilitates smooth collaboration between designers, printers, and clients.

🔹 Increases the accuracy and precision of printed materials.

2. Disadvantages of Printing Industry Standards Tolerances

🔹 Requires investment in calibrated equipment and skilled personnel.

🔹 Strict adherence to tolerances may limit creative flexibility.

🔹 Complexity in implementing and maintaining standards.

🔹 Potential delays due to the need for additional quality checks.

🔹 Initial learning curve for printers transitioning to standardized processes.

Frequently Asked Questions about Printing Industry Standards Tolerances

1. What are the key factors considered in printing industry standards tolerances?

The key factors considered in printing industry standards tolerances include color accuracy, registration, image clarity, dot gain, and substrate thickness.

2. How can printers ensure compliance with printing industry standards tolerances?

Printers can ensure compliance by calibrating their equipment regularly, using color management systems, and following standardized procedures for each printing job.

3. Are printing industry standards tolerances applicable to digital printing?

Yes, printing industry standards tolerances are applicable to both digital and offset printing technologies. These standards ensure consistency and quality across different printing platforms.

4. Can printing industry standards tolerances be customized for specific printing requirements?

Yes, printing industry standards tolerances can be customized to accommodate specific printing requirements. However, it is essential to strike a balance between customization and adherence to industry-wide standards.

5. How do printing industry standards tolerances benefit the packaging industry?

Printing industry standards tolerances benefit the packaging industry by ensuring accurate color reproduction, precise die-cutting, and proper folding and gluing, resulting in visually appealing and functional packaging materials.

Conclusion

In conclusion, adhering to printing industry standards tolerances is crucial for achieving high-quality and precise printed materials. These standards ensure consistency, accuracy, and customer satisfaction, while also reducing waste and enhancing brand reputation. By implementing standardized processes and investing in calibrated equipment, printers can elevate their printing capabilities and stay ahead in a competitive market. Embrace printing industry standards tolerances, and unlock the true potential of your printing endeavors.

Final Remarks

Printing industry standards tolerances provide a solid framework for maintaining quality and precision in the printing process. While they may require initial investments and adjustments, the long-term benefits far outweigh the challenges. It is essential for printing professionals to stay updated with the latest standards and continuously strive for improvement. Remember, precision and quality are the pillars that uphold the printing industry, and adherence to standards is the path to success.